“When genuine leather sofas in luxury boutiques develop cracks, when PU leather used in fast-moving consumer goods emits pungent odors, and when environmental regulations force manufacturers to seek alternatives—a silent material revolution is underway!”

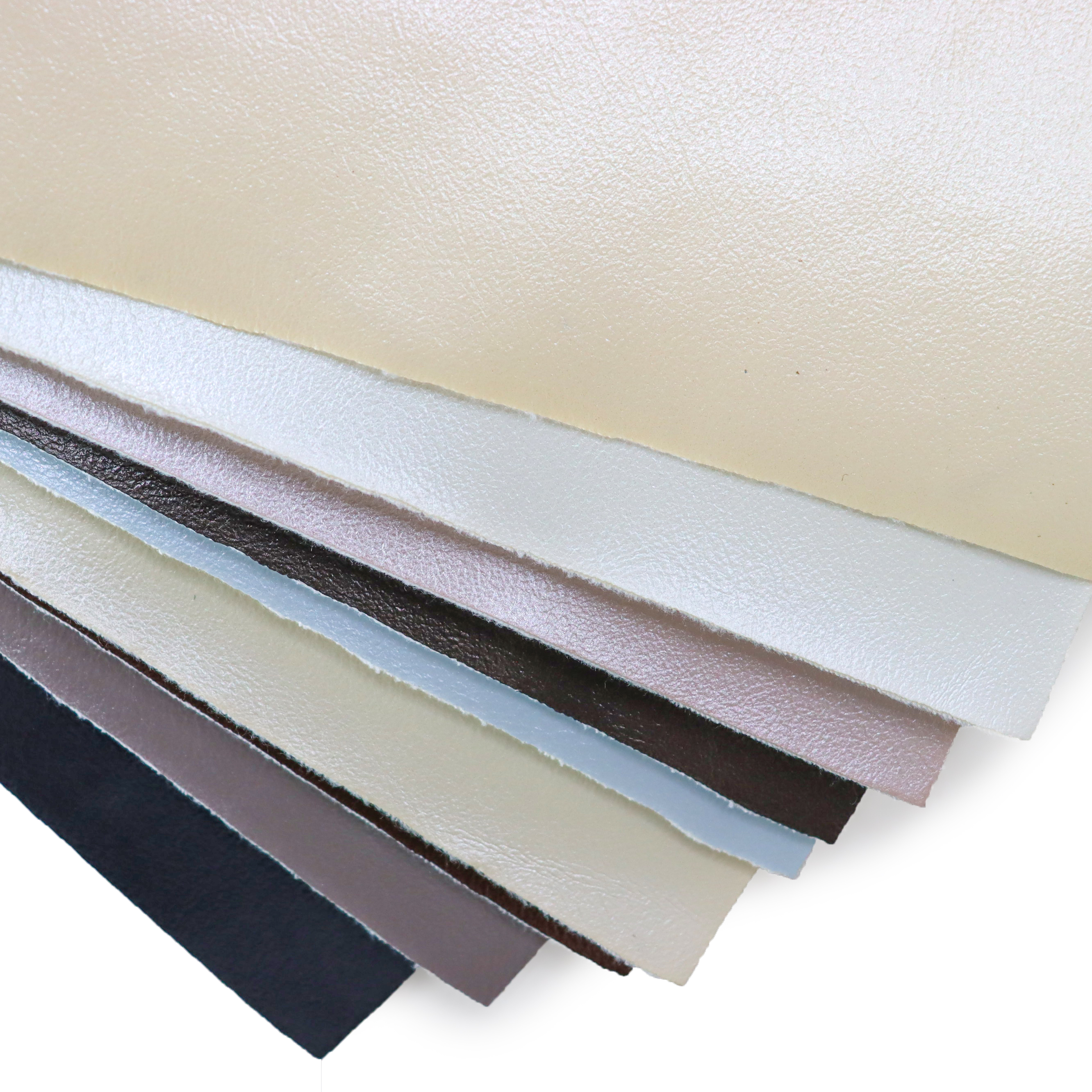

Three chronic issues with traditional materials have become industry-wide headaches: animal leather faces scarcity and high maintenance costs, synthetic leather suffers from poor durability and aging, while shared environmental pressures leave brands walking on thin ice. Now, full-silicon/semi-silicon leather emerges with breakthrough technology, redefining material performance ceilings through molecular-level innovation.

I. Eco-Friendly Stain Resistance

Waterproof & Stain-Resistant Tech

Featuring a nano-level dense cross-linked structure (porosity <0.5%), the surface exhibits a lotus-leaf effect. Test data shows: stubborn stains like red wine or soy sauce automatically form beads and roll off, requiring only a light wipe with tissue to restore the surface. Comparison test image: Left – conventional leather penetrated and moldy; Right – full-silicone material completely intact.

Flexibility Miracle Under Extreme Temperatures

After -20°C freezing and 80°C high-temperature cycling tests (per ISO 17683), material elongation fluctuation remains below 3% with 92% tear strength retention. This ensures consistent physical properties from Siberian winters to desert heatwaves. Special note: One outdoor brand reported 3x extended gear lifespan after use.

Non-Toxic Process Certification

The entire product line passes the EU REACH regulation’s screening for 23 hazardous substances, with volatile organic compound (VOC) emissions during production below the limit of detection (LOD). Workshop operators can handle raw materials directly without protective gear, achieving true green manufacturing.

II. Exceptional Value

In the “flex cycle resistance” metric determining durability, full-silicone materials achieve three times the performance of traditional leather. In the “yellowing resistance rating” measuring aging speed, their performance far exceeds industry standards. This magnitude of difference elevates end products from ‘disposables’ to “durable goods.”

III. Multi-Domain Applicability

Fashion Industry Innovation Case

A limited-edition handbag by a trendy brand showcased at Milan Design Week featured a matte-textured semi-silicone fabric paired with metal hardware. This design delivered waterproof functionality while evoking a futuristic tech aesthetic. Despite a 40% price premium over standard models, the bag became a hit due to its unique self-healing capability for minor scratches.

Medical Breakthrough Application

A sterile keyboard cover introduced in tertiary hospital operating rooms leverages the non-permeable and antibacterial properties (bacteria inhibition rate >99.9%) of full-silicone material. This boosts equipment cleaning efficiency by 70% and effectively reduces cross-infection risks.Automotive Interior Revolution

New energy vehicle manufacturers incorporate heat-insulating full-silicone leather with a thermal conductivity of just 0.12 W/m·K into seat ventilation systems. After summer sun exposure, its surface temperature remains 22°C lower than traditional materials, while its exclusive texture design delivers a luxurious visual experience.

This transcends mere material iteration—it represents humanity’s expansion of the boundaries of material understanding. As full-silicone/semi-silicone leather permeates every dimension of life, we witness the dawn of a new materials era. Every choice you make propels the industry toward higher quality and greater sustainability. Act now to secure a competitive edge for the next decade!

Post time: Aug-30-2025