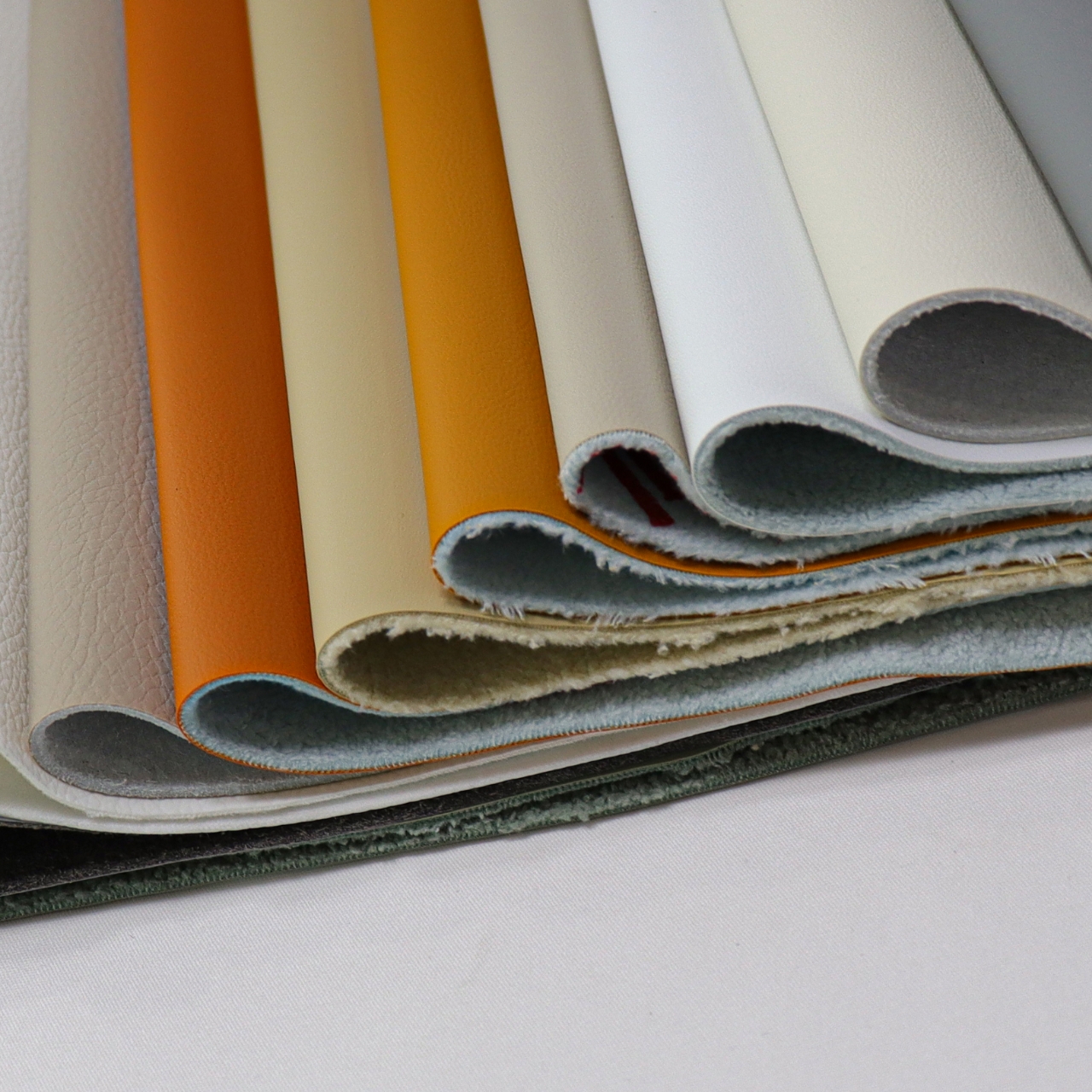

Gone are the days when luxury car interiors were defined solely by genuine animal hides. Today, a sophisticated synthetic material – silicone leather (often marketed as “silicone fabric” or simply “siloxane polymer coatings on substrate”) – is rapidly transforming cabin design across all segments, from entry-level models to high-end grand tourers. Offering an unprecedented blend of durability, aesthetics, sustainability, and performance, this innovative material is poised to become the new standard for automotive upholstery and trim. Let’s explore why silicone leather is driving this quiet revolution under the roof of modern vehicles.

Unmatched Durability & Resistance: Engineered for Harsh Environments

Automotive interiors face relentless abuse: intense UV radiation fading colors and cracking traditional materials; extreme temperature swings causing expansion, contraction, and stiffness; constant friction from passengers entering/exiting; spills ranging from coffee to ketchup; and the slow but sure degradation brought on by humidity and salt spray near coastal regions or during winter road treatments. Conventional leather struggles mightily under these conditions. Silicone leather laughs at such challenges.

- Superior Thermal Stability: It remains supple and comfortable even in scorching sun (often exceeding 80°C/176°F) without becoming sticky or stiff like PVC alternatives. Crucially, it stays flexible down to sub-zero temperatures, eliminating the brittle feel common in colder climates. This eliminates the risk of cracking seams over time due to thermal stress.

- Exceptional UV Resistance: Advanced silicone polymers inherently block damaging ultraviolet rays, preventing discoloration and material breakdown. Colors stay vibrant year after year, maintaining the vehicle’s showroom freshness much longer than dyed top grains which fade significantly faster. Tests show minimal color shift (ΔE < 2) after hundreds of hours equivalent to decades of use.

- Waterproof & Stain Proof: Unlike absorbent fabrics or porous leather that can trap liquids leading to mildew or stains, silicone leather features a non-porous surface. Wine spill? Wipe it away instantly. Mud tracked onto seats? Soap and water clean it effortlessly. No penetration means no permanent damage or odor absorption – critical for resale value and hygiene.

- Abrasions & Tear Resistance: Its robust woven base layer (typically polyester or nylon) reinforced with the dense silicone coating creates a composite far more resistant to scuffs, scrapes, and punctures than natural leather alone. High abrasion resistance ratings (ASTM tested often exceeding 50,000 double rub cycles) ensure it maintains its appearance through years of heavy use.

Driving Towards the Future

As automakers strive to balance luxury aspirations with environmental responsibilities, cost pressures, performance demands, and global supply chain resilience, silicone leather emerges as a near-optimal solution. Its ability to replicate the sensory experience of genuine leather while surpassing it in key functional areas like durability, ease of care, and sustainability represents a paradigm shift in automotive interior design philosophy. From bustling urban commuter hatchbacks subjected to daily abuse to opulent flagshimodels cruising coastal highways under brutal sun, silicone leather proves its worth silently, day after day, mile after mile. It’s not just an alternative—it’s quickly becoming the intelligent choice shaping how we experience mobility interiors today and tomorrow.

Post time: Sep-12-2025